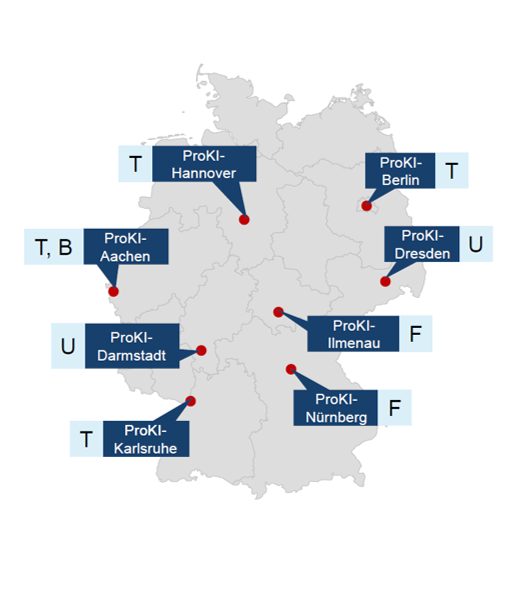

The TU Ilmenau strengthens small and medium-sized enterprises (SMEs) in global competition. As one of eight locations nationwide, a new Center for Artificial Intelligence (AI) at the Production Technology Group supports manufacturing companies in integrating AI into production processes. The center is part of the "ProKI-Netz" demonstration and transfer network and will be funded by the German Federal Ministry of Education and Research with almost two million euros over the next two years.

ProKI Center Ilmenau: New Transfer Center Optimizes Industrial Production Using Artificial Intelligence

Whether in the automotive industry, in mechanical engineering or in the manufacture of conventional household appliances - the joining of materials is one of the core activities in industrial production. During the course of automated manufacturing, errors can occur time and again, e.g. due to inaccurate settings of process parameters during welding. Product quality losses, a high reject rate or longer production downtimes combined with financial losses are among the consequences. It is therefore important to optimally set the parameters on which the manufacturing process is based, to check quality automatically and to integrate the knowledge of skilled workers into machine processes. This is where AI can provide significant support.

Individual AI solutions for every company

As part of the ProKI network, the TU Ilmenau will support companies in the manufacturing sector with its know-how in the field of joining to produce more effectively. The experts from a total of five departments involved in the project - ProductionTechnology, Quality Assurance and Industrial Image Processing, Plastics Technology, Data-intensive Systems and Visualization Group, and Innovation Management - are available to companies from all over Germany as contact persons. If required, they visit the companies on site, check the production for its effectiveness, collect data of the manufacturing processes in close cooperation and show possibilities of preparation, analysis, evaluation and algorithmic further processing of these data. In each case, individually tailored to a company, they develop needs-based AI solutions such as a traffic light system that displays errors in production in real time. Workers on the shop floor can then intervene quickly and take countermeasures thanks to AI support.

Dr.-Ing. Jörg Hildebrand, research associate at the Production Technology Group and initiator of the ProKI Center Ilmenau, would like to sensitize manufacturing companies to the opportunities offered by the use of AI:

As a manufacturing technology specialist, we are predestined with our years of experience to transfer our knowledge into practice. SMEs in particular, which often do not have their own research and development department, can benefit from our expertise.

Dr. Sebastian Gerth, head of the ProKI Center at TU Ilmenau, sees AI-assisted manufacturing as a way to counteract the shortage of skilled workers in industry:

Today, companies rely primarily on the experience of competent production managers, who notice quite quickly when a production process is not running optimally and quality losses are to be expected. This knowledge is lost either because the employees go into well-earned retirement or because they gain a foothold in other companies. It is therefore advisable to map this knowledge technologically - for example, by training an AI and later optimizing the corresponding processes automatically on the basis of this data. Seen in this light, AI is also a means of counteracting the shortage of skilled workers.

Contact

Dr. Sebastian Gerth

Head of the ProKI Center Ilmenau