In a joint project with two small and medium-sized enterprises (SMEs), researchers at the Electronics Technology Group at the TU Ilmenau have succeeded in developing a sensor element based on low-temperature ceramics, so-called LTCCs, with which the dew point of acidic gases from exhaust systems can be determined and controlled in real time. In this way, the exhaust gas temperature of industrial fossil fuel plants can be kept low and CO2 emission reduced without acid condensing in the exhaust tract and destroying the chimney.

Burning fossil fuels such as coal, crude oil or natural gas in industrial plants releases large quantities of acidic gases containing sulfur or carbon dioxide (CO2). The higher the exhaust gas temperature, the greater the emission of the climate-damaging CO2. The aim of the scientists in the KerTauSens project was therefore to develop a sensor that can be used to determine the dew point temperature of exhaust systems in-situ, i.e. in the exhaust tract, and monitor it in real time so that the exhaust gas temperature can be kept low without the gas condensing. This is because if the temperature falls below a certain value - the so-called dew point - the gas precipitates as condensate inside the chimney. The acids contained in the condensate deposits can decompose and destroy the chimney from the inside.

One of the challenges in developing the dew point sensor was the extremely high temperatures of up to 250 degrees in the fossil flue systems. The material used for the sensor therefore had to be heat-resistant. In addition, the scientists faced other challenges:

These included, for example, the need to keep the sensor in operation permanently, but also an acid-resistant sensor surface for measuring electrical resistance and the low heat capacity in the sensor area for efficient cooling

explains Prof. Jens Müller, head of the Electronics Technology Group, who led the project at the TU Ilmenau.

Due to these operating conditions, a ceramic system based on low-temperature ceramics was the obvious choice.

Use of the sensor also possible under harsh conditions

Compared to traditional circuit board materials in electronic circuits, low-temperature ceramics, so-called low-temperature cofired ceramics (LTCC) - low-sintering multilayer ceramics - can also be used under harsh operating conditions, such as contact with aggressive materials, strong mechanical stresses or high temperatures. By also reducing the number of layers of ceramics in the circuit, the researchers were able to achieve a locally lower heat capacity of the sensor, allowing it to heat up and cool down quickly and enabling measurement at shorter intervals.

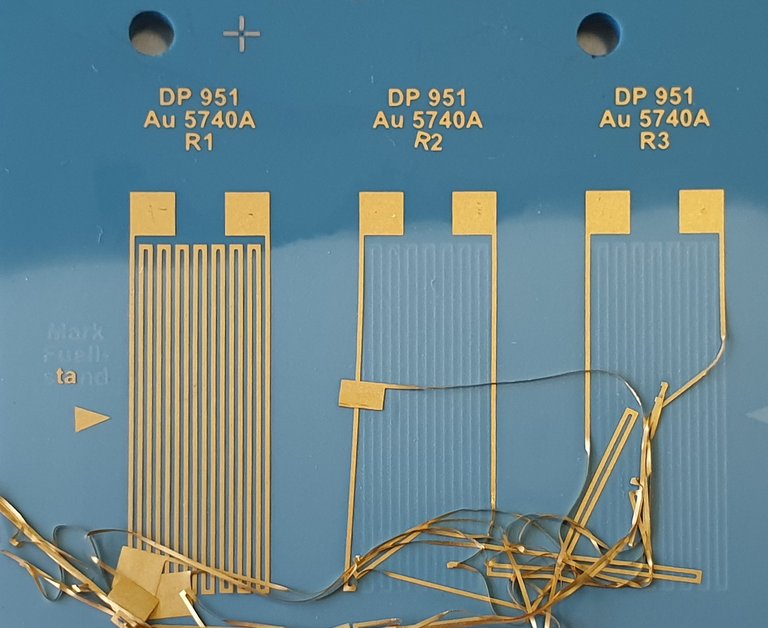

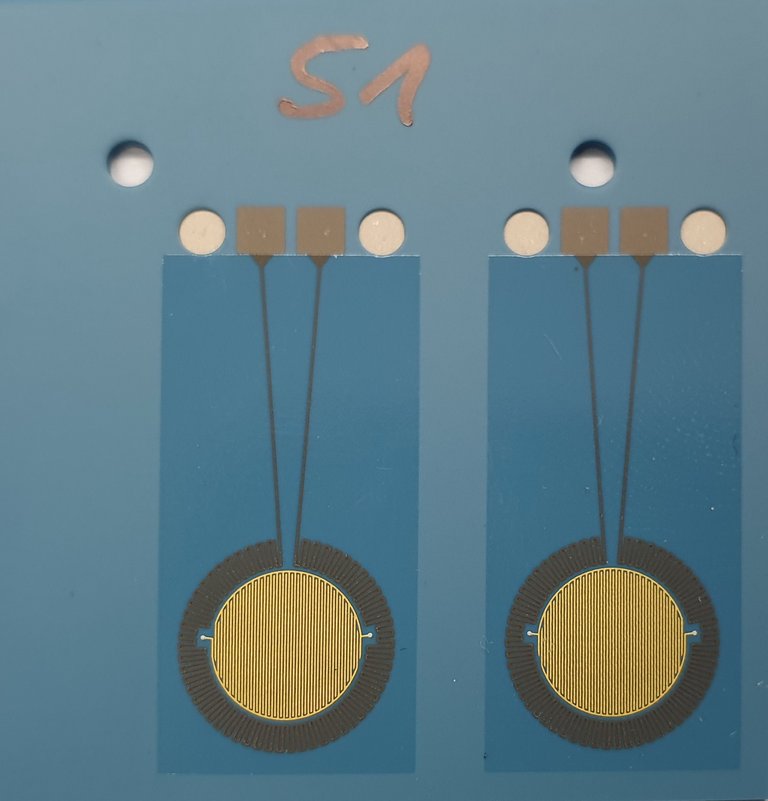

Development work focused on optimizing the signal swing in the event that the dew point is reached, as well as on the acid resistance of the sensor. At the beginning of the project, it was not clear whether a resistive or capacitive measurement principle should be used. In resistive-based measurement, the metallic electrodes are in direct contact with the acidic gas, while in capacitive measurement, a cover layer lies between the electrode structure and the dew layer. In both cases, so-called interdigital electrodes are used, which consist of a pair of comb-shaped, interlocked finger-like electrodes. In an acid strength test, the scientists tested samples of two commercial low-temperature ceramics with different screen-printed noble metal electrodes in solutions containing different concentrations of nitric and sulfuric acid over a period of thirty days. For all material combinations, there were color changes in the ceramics, and the structures detached from the LTCC (loss of adhesion, Fig. 1). The metallic structures themselves remained intact. Therefore, the research team decided to use the capacitive measurement principle with a cover layer between the electrode structure and the dew layer. In a further acid resistance test, the scientists identified a glass coating from a variety of cover glasses that provided stable protection under the test conditions.

Cost-effective, industrial system for improving the carbon footprint

With the aid of the sensor developed in this way, it is possible to detect the acid dew point and lower the exhaust gas temperature to a temperature just a few Kelvin above the acid dew point temperature, so that there is no risk of condensation and damage to the chimney due to corrosion:

With the help of low-temperature ceramics, we have succeeded in developing a cost-effective, industrially suitable and real-time measurement system with which the acid dew point in the exhaust gas stream can be determined precisely and continuously.

explains Prof. Müller.

This can not only improve plant safety and maintenance, but also optimize the use of energy sources in industrial plants and reduce climate-damagingCO2 emissions.

The research in the KerTauSens project was funded as part of the BMBF ZIM program "Central Innovation Program for Small and Medium-sized Enterprises (SMEs)". The company Consens from Ilmenau was responsible for the evaluation electronics and Electronics & Sensors from Ilmenau for the high-temperature connection technology.

Contact

Prof. Jens Müller

Head of the Electronics Technology Group