In the E4SM project, scientists from seven disciplines at TU Ilmenau, together with the Thuringian Center for Mechanical Engineering and the Mittelstand-Digital Zentrum Ilmenau, are researching innovative scientific methods for the development, implementation, setup and operation of machine learning (ML) based assistance systems for smart manufacturing in industrial applications..In the context of Industry 4.0, the developed methodologies and techniques are transferred and demonstrated on the industrial applications of "jigless laser beam welding" and "multi-variant assembly processes". The first solutions, which will primarily benefit small and medium-sized companies, will be presented at the Hannover Messe from May 30 to June 2, 2022.

The digitization of industry is dramatically changing the way we produce, do business and work. At the heart of Industry 4.0 is the intelligent networking of processes and machines using modern communication and information technologies. The aim is to use all the data collected on a production process with the help of artificial intelligence (AI), i.e. intelligent, adaptive software, to improve the quality of production processes and increase efficiency and/or the degree of automation.

The "Engineering for Smart Manufacturing" (E4SM) research project, which aims to provide industrial companies with innovative techniques for smart manufacturing and assembly, is also dedicated to this goal. The research focuses on the requirements and special features of manufacturing and assembly processes in small and medium-sized enterprises (SMEs). The technologies are currently being tested in two application scenarios that are typical for SMEs and are particularly data-intensive: laser beam welding and multi-variant assembly processes in the production of small series.

Laser beam welding without expensive clamping devices

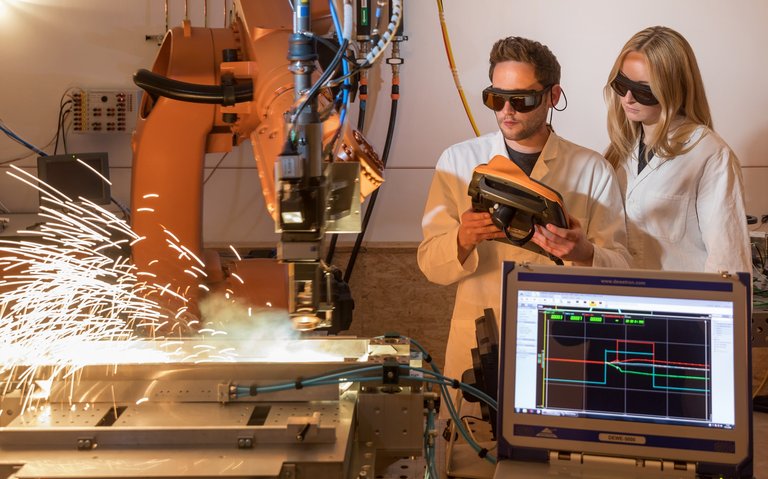

Laser beam welding is one of the so-called joining manufacturing processes. In industry, it is used, among other things, to join metallic components together. In this process, energy is added at specific points by means of a laser beam, and usually no filler material is used. Thanks to the energy-intensive laser beam, welding can be carried out at very high speed in this process. Other advantages include low thermal distortion in the component and a very narrow and precise weld seam. Laser welding is currently used primarily in high-precision applications in toolmaking, the automotive industry, steel construction, but also in shipbuilding or aerospace and other industries.

"Currently, such welding processes require large and expensive clamping devices to hold the sheets to be joined together during welding so that no gap is created between the sheets due to the physical forces caused by the laser's energy during melting," explains Prof. Jean-Pierre Bergmann, head of the Production Technology Group at TU Ilmenau. To enable companies to use laser beam welding without fixtures in the future, the TU Ilmenau is developing innovative processes in the E4SM project in which robot arms hold the two sheets together and compensate for physical forces that occur during welding so that no gap is created between the sheets. To achieve the best possible welding results, an artificial intelligence system continuously analyzes the welding process and derives the necessary motion commands for the robot arms.

This is a highly complex, computationally intensive machine learning process in which large amounts of data - images, temperature and force measurements - are exchanged and which requires a great deal of expertise in data science and software development: "Since the welding process only lasts a few seconds in total, predictions about how the weld seam will develop must be made very quickly and at an early stage, i.e. in real time, so that the robot can react in good time and counteract as soon as it is foreseeable that a joint gap will develop," explains Prof. Groß, head of the Neuroinformatics and Cognitive Robotics Group, who is coordinating the E4SM project.

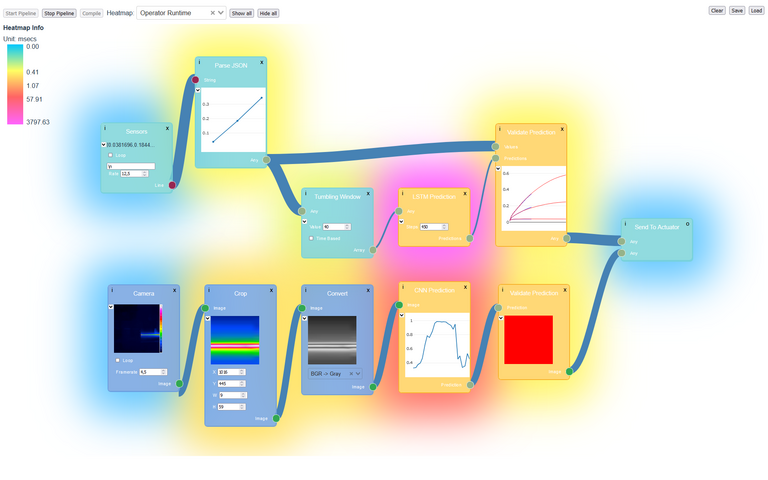

To make such multi-layered processes, especially those with AI components, more manageable for SMEs, the scientists in E4SM have developed a visual and interactive editor with which data processing chains, so-called pipelines, can be created, tested and automatically optimized for productive use. With a high degree of abstraction, predefined data transformations can be strung together - without deep expertise in software development - and extensive live monitoring informs the user in real time about the pipeline's state and processed data.

For companies, jigless laser beam welding with the help of artificial intelligence brings several advantages at once, according to Prof. Groß: "For one thing, companies can use it to make significant cost savings when introducing new production lines. For another, robotic arms can be reused when production lines change, whereas customized fixtures can become unusable in these cases."

Safe collaboration between humans and robots at shared workspaces

Another challenge in industrial manufacturing that the project addresses relates to the production of small batches. "When manufacturing small batches, it is generally not cost-effective to set up fully automated production chains," explains Prof. Bergmann. Accordingly, companies that offer the production of small batches often modify their production chains to meet the individual wishes of their customers. In manufacturing, therefore, there is a high variance in the number of workpieces to be produced. "The problem is that only a low level of automation can often be achieved with this muti-variant assembly, and production is correspondingly labor- and cost-intensive."

In order to make the production of small batches more efficient and increase the degree of automation, the TU Ilmenau is developing mobile, autonomously acting assistance robots in the E4SM project that can support the people working in assembly, for example by handing objects to them. "It's not about a robot replacing a human in the assembly process and processing a task more quickly, but about new synergies being created through the collaboration between humans and robots," says Prof. Groß. To make this collaboration reliable and safe at a shared workspace, the scientists in the project are developing artificial intelligence that helps the robot perceive its environment, independently analyze the assembly process and autonomously derive meaningful, proactive actions that support the worker during assembly. "Until now, such adaptive software components have hardly been found in industrial assembly processes," says Prof. Groß. "For the first time, we are extending previous learning methods to include corresponding components, thus laying all the necessary foundations to enable safe cooperation between humans and robots in a shared workspace."

In follow-up projects, the TU Ilmenau would like to apply the developed solutions together with companies and thus make the use of machine learning and assistance systems in industrial processes more plannable and controllable, especially for small and medium-sized enterprises , and lower entry barriers when introducing the technology.

More about the E4SM project

The E4SM project is funded by the Carl Zeiss Foundation with three million euros over five years and combines the expertise of seven different departments at TU Ilmenau in the fields of neuroinformatics and cognitive robotics (NIKR), telematics/computer networks, production technology, data-intensive systems and visualization (dAI.SY), quality assurance and industrial image processing (QSIB), databases and information systems, systems and software engineering. A new junior research group has also been established, staffed by experts in the field of machine learning.

The project is accompanied by a high-profile corporate advisory board that includes the Honda Research Institute Europe, Robert Bosch GmbH, LASO tech Systems GmbH, Metralabs GmbH, Henkel and Roth GmbH, and TÜV Thüringen e.V.

[Translate to English:] Sichere Zusammenarbeit von Menschen und Robotern an geteilten Arbeitsplätzen

[Translate to English:]

[Translate to English:]

Eine weitere Herausforderung in der industriellen Fertigung, die das Projekt adressiert, betrifft die Produktion von Kleinserien: „Bei der Fertigung von Kleinserien ist der Aufbau vollautomatisierter Produktionsketten in der Regel nicht kosteneffizient umsetzbar“, erklärt Prof. Bergmann. Unternehmen, die die Produktion kleiner Serien anbieten, ändern dementsprechend häufig ihre Produktionsketten, um auf individuelle Wünsche der Auftraggeber einzugehen. Bei der Fertigung kommt es also zu einer hohen Varianz an zu fertigenden Werkstücken. „Problematisch ist, dass sich bei dieser variantenreichen Montage häufig ein nur geringer Automatisierungsgrad erreichen lässt und die Produktion entsprechend personal- und kostenintensiv ist.“

Um die Produktion von Kleinserien effizienter zu gestalten und den Grad der Automatisierung zu steigern, entwickelt die TU Ilmenau im Projekt E4SM mobile, autonom agierende Assistenzroboter, die die in der Montage tätigen Personen unterstützen können, indem sie beispielsweise Gegenstände anreichen. „Es geht also nicht darum, dass ein Roboter einen Menschen im Montageprozess ersetzt und eine Aufgabe schneller bearbeitet, sondern dass durch die Zusammenarbeit von Mensch und Roboter neue Synergien entstehen“, so Prof. Groß. Um diese Zusammenarbeit an einem geteilten Arbeitsplatz zuverlässig und sicher zu gestalten, entwickeln die Wissenschaftler im Projekt eine Künstliche Intelligenz, die dem Roboter dabei hilft, seine Umgebung wahrzunehmen, den Montageprozess eigenständig zu analysieren und selbständig sinnvolle, proaktive Handlungen abzuleiten, die den Werker bei der Montage unterstützen. „Bisher sind solche lernfähigen Softwarekomponenten kaum in industriellen Montageprozessen zu finden“, so Prof. Groß. „Wir erweitern bisherige Lernverfahren erstmals um entsprechende Komponenten und legen damit alle notwendigen Grundlagen, um eine sichere Zusammenarbeit von Menschen und Robotern an einem gemeinsamen Arbeitsplatz zu ermöglichen.“

In Folgeprojekten möchte die TU Ilmenau die entwickelten Lösungen gemeinsam mit Unternehmen zur Anwendung bringen und so den Einsatz von maschinellem Lernen und Assistenzsystemen in industriellen Prozessen insbesondere für kleine und mittlere Unternehmen besser plan- und beherrschbar gestalten und Einstiegshürden bei der Einführung der Technik senken.

Mehr über das Projekt E4SM

Das Projekt E4SM wird von der Carl-Zeiss-Stiftung mit drei Millionen Euro über fünf Jahre gefördert und vereint die Kompetenzen sieben verschiedener Fachgebiete der TU Ilmenau auf den Gebieten Neuroinformatik und Kognitive Robotik (NIKR), Telematik/Rechnernetze, Fertigungstechnik, Data-intensive Systems and Visualization (dAI.SY), Qualitätssicherung und industrielle Bildverarbeitung (QSIB), Datenbanken und Informationssysteme, System- und Software-Engineering. Außerdem wurde eine neue Nachwuchsforschergruppe eingerichtet, die mit Experten auf dem Gebiet des maschinellen Lernens besetzt ist.

Begleitet wird das Projekt von einem hochkarätigen Unternehmensbeirat, zu dem das Honda Research Institute Europe, die Robert Bosch GmbH, die LASO tech Systems GmbH, die Metralabs GmbH, die Henkel und Roth GmbH und der TÜV Thüringen e.V. gehören.

Contact

Prof. Horst-Michael Groß

Head of Neuroinformatics and Cognitive Robotics