Electric drives in a wide variety of shapes, sizes and power ratings characterize the profile of the Small Electrical Drives Group at the TU Ilmenau. In teaching and both basic and application-oriented research, the scientists dive deep into the subject of electric motors and develop the right motor for every product.

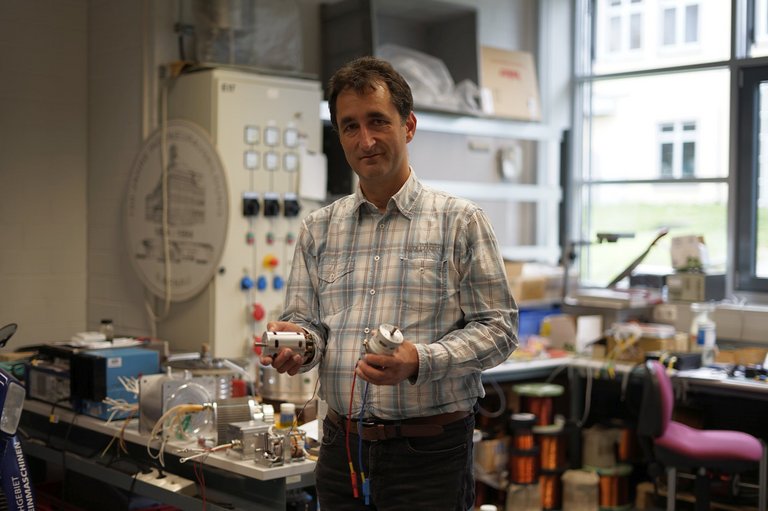

Whether in toothbrushes, cars or industrial machines - it is hard to imagine our everyday lives without electric drives. The principle of converting electrical energy into mechanical energy is already well known, but Prof. Andreas Möckel, acting head of the Small Electrical Drives Group at TU Ilmenau, knows that details are crucial: How big and heavy, for example, should a drive be so that a conventional kitchen appliance fits well in the hand? How high should the speed be so that the appliance delivers optimum performance? And how can it be manufactured cost-effectively and at the same time last a long time for use? At his department, the scientist deals with these and other questions, researching and developing electric drives for various applications. He explains what is important in electric drives:

The art of our science is to find the optimal compromise for each application. Although we have known how an electric motor works for more than 150 years, advances in technology and materials science are driving our field forward.

Laboratory test measurements

To ensure that each device is equipped with the optimal drive, Professor Möckel and his team are working on the methodology of design and optimization up to fully automated self-learning processes. The symbiosis of progress driven by technology and materials as well as the steadily growing possibilities of calculation and simulation paired with power-electronically realized control methods provide a wide field of activity for both application-oriented and basic research. The concepts are tested and optimized on test rigs with regard to their practical suitability. The scientists carry out measurements in laboratory tests and check, among other things, to what extent the structural modeling as well as the material parameters offer accuracy in the calculation. In particular, material changes due to machining and parasitic effects mean that no valid calculation is possible, especially for smaller or also highly utilized engines of greater power, without metrological validation.

Whereas in its early days the Small Electrical Drives Group was primarily concerned with small drives, over the last ten years the teaching and research profile of the scientists has expanded to include electric drives up to 200 kilowatts, which can be assigned to a medium power range. These are researched as well as motors for small devices such as auxiliary and auxiliary drives for vehicles. Especially electric drives in vehicle technology are a main focus of the department today. In cooperation with the Thuringian Innovation Center Mobility, the department is supporting the electric drive part of the KREARÖR project, which is closely linked to the CAMIL project, in which automated minibuses are integrated into Ilmenau's bus transport system. In the KREATÖR project, it is to be examined how universally operational an electric drive may be for different route profiles and from which change in the area of application a new design is more advantageous.

Practical teaching

For several years, the Group has also been collaborating with the Institute of Vehicle Concepts of the German Aerospace Center - most recently on the development of lightweight auxiliary and secondary engines in the IDEAL project, which could be used in trucks, for example. Research into autonomous driving is also particularly exciting for the scientists at present, as Prof. Möckel explains:

Autonomous driving is a very interesting field for us in connection with the monitoring of electric drives. We are currently looking at the question of how the autonomous system can make a prediction about how far advanced the wear of a motor is and how long its service life is. The use of AI-based methods is particularly exciting here. Thanks to the connection with the Data-intensive Systems and Visualization Group and the support of Prof. Mäder, the first successful approaches have already emerged.

At the Small Electrical Drives Group, the scientists not only attach great importance to university-based research, but also to practical teaching to illustrate the theoretical subject matter. In the machine hall of the Kirchhoff Building, students and doctoral candidates are given the opportunity to assemble and commission motors for a wide variety of applications in the laboratory and to actively participate in research projects. In the late bachelor's program and especially in the master's program, they acquire fundamental knowledge for this purpose, including the understanding and application of the theory of electrical machines, the further development and synthesis of special designs, and the methodology of design and optimization up to fully automated design. The accompanying practical work should enable them to better understand and develop the theoretical knowledge, says Prof. Möckel:

With the knowledge of electric drives, underpinned by the practical work, we want to enable our students to grow beyond themselves. At the TU Ilmenau, we deal with the subject matter in great depth, which gives our students the qualifications to work on current topics in electrical machines, even at the highest level.

Contact

Prof. Andreas Möckel

Acting Head of the Small Electrical Drives Group