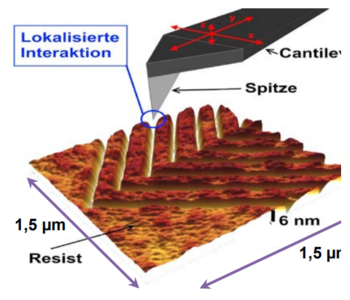

For 40 years now the semiconductor industry has been following Moore’s Law with astonishing consistency. Despite far-reaching further developments in optical lithography, it is becoming evident that structure sizes of < 20 nm can only be achieved with great effort using known methods. Meanwhile, the fundamental challenge is in the development of alternative production technologies particularly for micro- and nanotechnologies which can measure and work on the atomic scale in steadily increasing work areas of several hundred millimeters in diameter. Tip-based nanofabrication procedures offer a great potential already facilitating a structuring in sub -10 nm-areas, but so far only in small processing areas (a few 100 µm2 ), at low speeds and with limited precision. The Research Training Group pursues the goal of synergetically connecting advanced nanofabrication techniques with the outstanding features of the nanopositioning and nanomeasuring machines (NPM machines) in such a way that new scale-independent spacious solutions are developed.

This international and interdisciplinary project has been financed by Deutsche Forschungsgemeinschaft DFG (German Research Foundation) since April 2017. The current funding period ends on 30 September 2021 and supports 13 PhD students from various scientific fields, thus contributing to the very ambitious goal. The guiding theme is based on the consistent application and expansion of error-minimum metrological principles referring to nanofabrication systems and in the derivation and analysis of new opportunities and strategies in nanofabrication. The innovative character of the project is in the connection of efficient tip-and laser-based micro and nanofabrication techniques with the unique opportunities of the high-level nanopositioning and nanomeasuring techniques developed at TU Ilmenau for offering entirely new opportunities in nanofabrication.

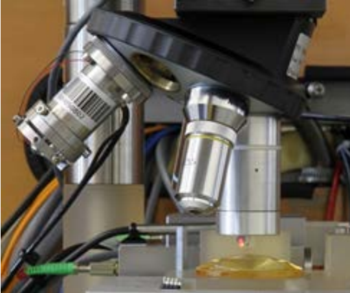

Combining the latest AFM tip-based nanofabrication technologies with the NPM-technique should determine to what extent minute structures can be produced efficiently on large areas. The first generation of PhD students in this project will already test the tip-based structuring of wafers under 10 nm in areas up to25 x 25 mm² with the nanopositioning and nanomeasuring machine. Laser-based sub-wavelength machining procedures in conjunction with NPM technique shall equally open up opportunities of real 3D-nanofabrication of highest precision on optical, uneven precision surfaces (aspheres/free-form surfaces). The Research Training Group is involved in the following three research areas: A Tip-based nanofabrication B Laser-based micro- and nanofabrication C Nanofabrication on free-form surfaces These three research areas are combined with other wider spheres of work: 1. Theory and metrology 2. Tools/parallelization 3. Kinematics and control and to the research matrix given in table 1.

For several years the applicants involved have been cooperating successfully in the SFB (Collaborative Research Centre) for Nanopositioning and Nanomeasuring Machines, in the Research Training Group for Lorentz Force, the research project Inno-Profile Force Measurement Technology and the core facility for Micro-Nano-Integration at IMN MacroNano® at TU Ilmenau.

Contact person:

Head of the project:

Prof. Dr.-Ing. habil. Eberhard Manske

Chair of the Group of Production and Precision Measurement Technology

PF 100565

D-98684 Ilmenau

Tel.: +49 3677 69-1250 bzw. -5050

Fax: +49 3677 69-1412 bzw. -5052

eberhard.manske@tu-ilmenau.de