The aim of this project is to set up an adaptive production management system at Kern Technik in Schleusingen.

Due to constantly changing economical context, technical and organizational conditions (call-off behavior, batch sizes), internal optimization solutions as well as planning and control systems are necessary in many manufacturing companies to ensure the efficiency and flexibility of all processes in the internal value chain.

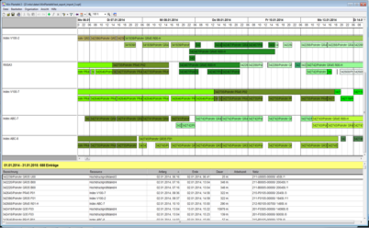

The methods and tools to be used in the areas of production planning and control, logistics/inventory management, scheduling, and controlling must be designed to be more flexible and responsive under the current demands of the market and must also meet increasing requirements in the future with regard to adherence to schedules and quantities.

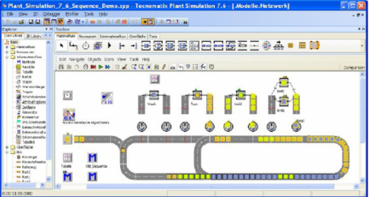

Due to the manifold stochastic influences, modern simulation methods can provide meaningful decision support.

The aim of the project is, among other things, to define a suitable set of tools to support production management and to introduce and support their use.